-40%

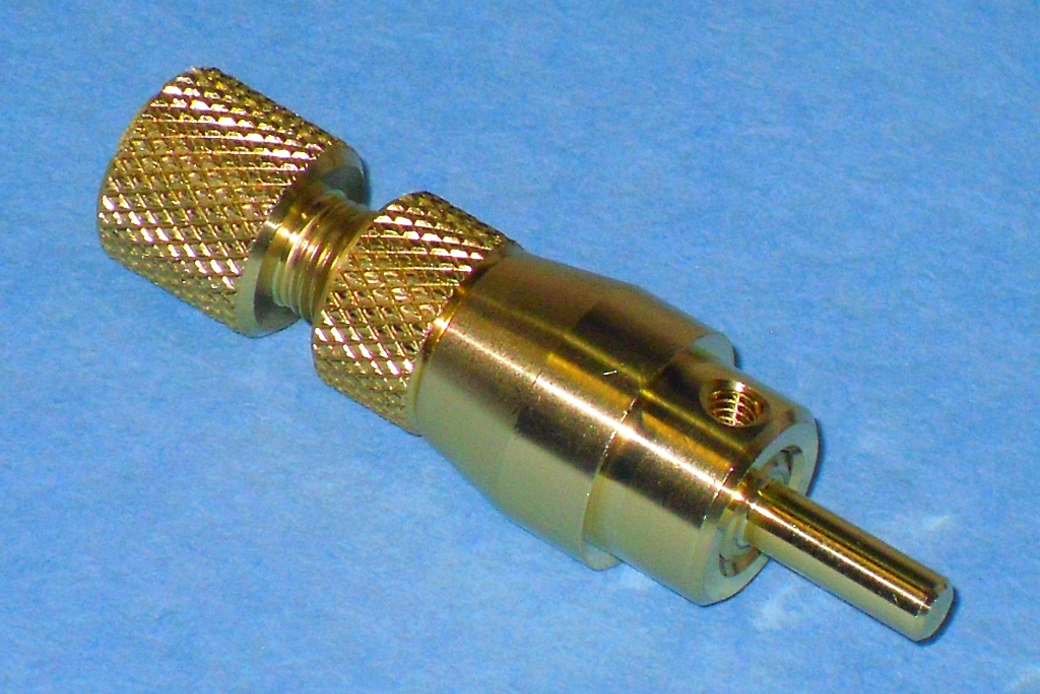

BRASS POWER ADJUSTER fits Crosman 1377, 1322, 1300KT, 2289G Backpacker & PC77

$ 18.48

- Description

- Size Guide

Description

This listing complies with eBay's air gun guidelines found here and I will only sell and ship air guns to buyers in jurisdictions where permitted by applicable laws - http://pages.ebay.com/help/policies/firearms-weapons-knives.htmlThis is the newest version of the MAGNUM ADJUSTER for 13XX. It's machined from solid 360 brass. It has a locking collar and tick marks on the back of the knob to help gauge and maintain adjustments. The hammer spring can be changed by backing the adjuster knob all the way out. It's compatible with all the hammer springs we have listed. It fits 1377C, 1322C, PC77, P1377, P1322, 2289G Backpacker and 1300KT models.

For maximum power, set spring tension to the minimum needed for the power level to peak. There's a valve-stem rebound effect that happens when the hammer hits the valve too hard, this causes power loss because the valve closes faster. Very few in the industry are aware of that, most suggest using the strongest possible spring which is the worst possible way to do it.

For the best accuracy, use the least amount of spring tension needed for the gun to fire well. This keeps vibration, hammer bounce and trigger pull to a minimum and reduces wear on trigger group, valve and hammer components.

The small diameter of this adjuster leaves room for about two full threads of mounting-screw engagement. This is more than sufficient due to the high strength of the aluminum alloy. The screws should be snugged down firmly but not heavily torqued. A small amount of medium-strength threadlocker can be used on the first few threads of the screws. This will keep them from loosening but still be removable. We haven't had any issues with damaged threads and we've sold thousands of these adjusters since 2009. This info is included only as a precaution for those who tend to over-tighten things to an extreme.

MOUNTING INSTRUCTIONS

The original Crosman screws are a poor fit and hit the threads on the adjuster knob. Alloy-steel socket screws and a spacer washer are included. The washer is needed for the longer 11/16" screw, otherwise it may rub on the threads of the adjustment knob. Do not add a washer to the 1/4" screw, it's a perfect fit. Both screws require a 3/32 hex wrench which is not included.

INSTALLATION STEPS

1)

Make sure the gun is unloaded, uncocked and empty of pressure. Remove the rear trigger frame and rear breech screws. Remove the tube plug which is where the adjuster will mount. It usually falls or lightly ejects out if you don't hold it while removing the screws. Install the threaded tube plug that’s part of the power adjuster, leave the threaded knob off until the tube plug is screwed in place. Place the hammer spring on the guide at the tip of the threaded adjuster knob. Make sure the spring goes into the back of the hammer as you thread the knob into the end tube plug. If you turn the adjuster knob too far in the hammer will not pull back far enough to catch on the sear. Adjust to full spring compression with the gun cocked, stop when you feel the spring is fully compressed, do not force it further. Back the adjuster out two full turns, this is the strongest setting that works smoothly in most cases. Peak power is often at a lower setting due to the valve stem closing faster (rebounding) from too much hammer spring force as mentioned above.

2)

With a power adjuster, custom valve or stronger hammer spring it’s typical to have to cock the gun to get the valve to seal so it can be pressurized.

3)

The more striker spring tension you have the harder it becomes to pull back the bolt. With a heavier spring and/or power adjuster, the bolt will pull back easier with your finger hooked around the front of the handle close to the breech. If done in one quick motion the bolt will pull back smoothly. If done slow or holding the handle further away from the breech the bolt may tend to bind or work rough. A loose-fitting pin in the top of the hammer is the most common cause of rough cocking. The custom hammers with a thread-in cocking pin we have listed eliminate this issue and produce more power by opening the valve stem further.